Components

without compromise

We engineer custom components with purpose for miles more efficiency.

Choose from a range of additional fitments and services carried out in house:

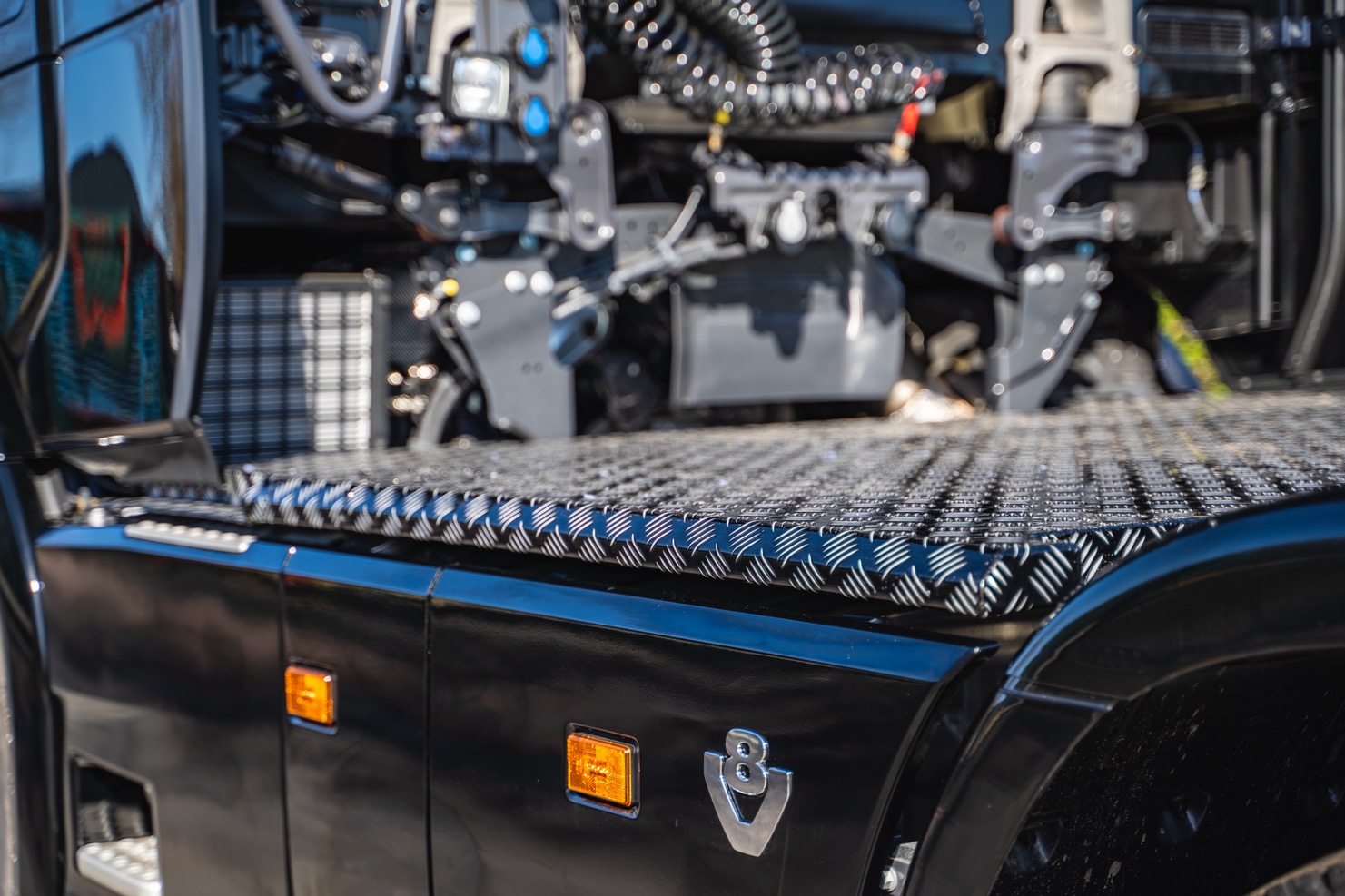

- Toolboxes

- Catwalks

- Fully approved fuel tanks

- Sideskirts and side infills

- Steps

- Wet kits

- Heavy haulage

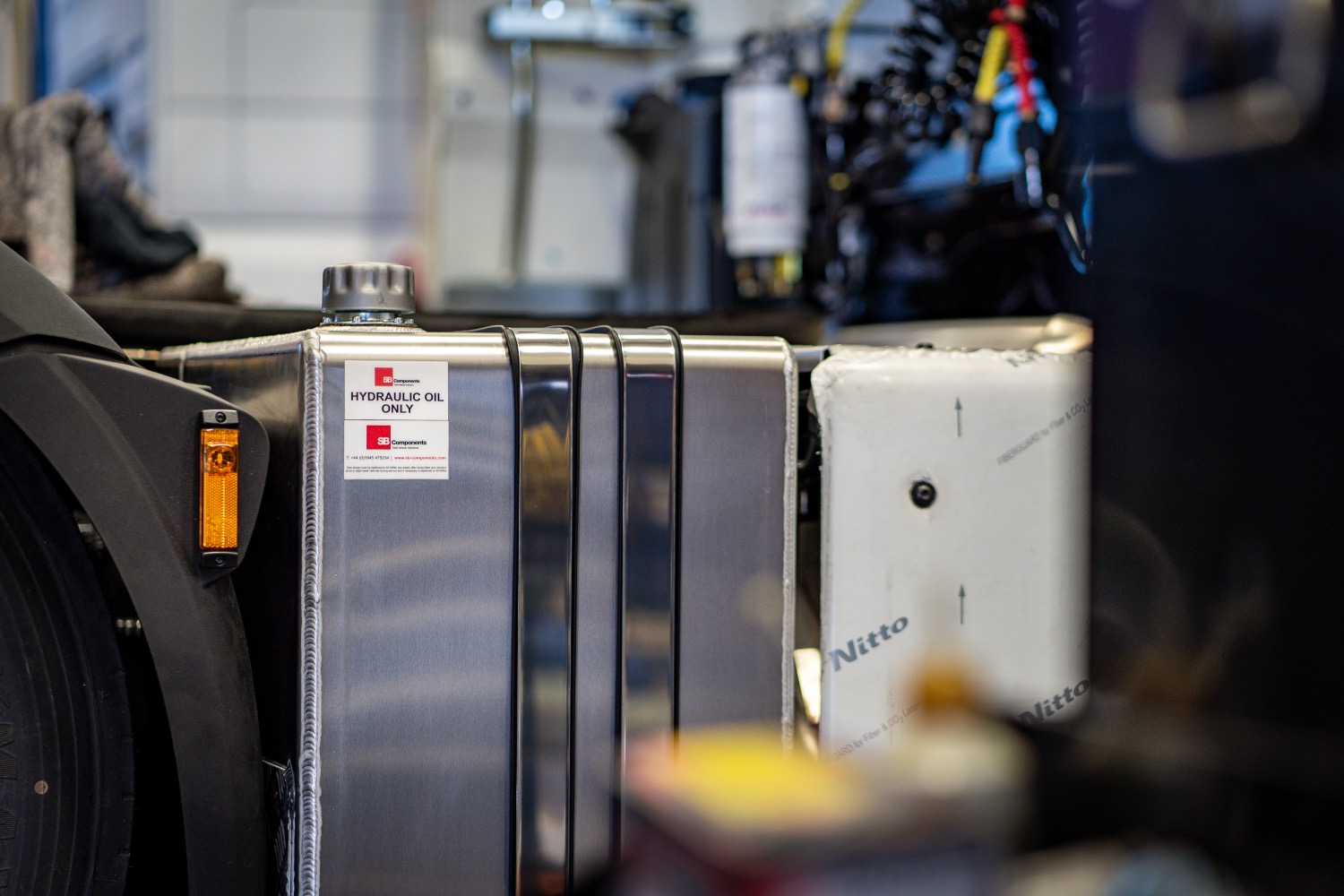

- Hydraulic oil tanks

- Tiss anti-siphon devices

- Warning alarms

- In-cab electrical devices and lights

- Repairs and maintenance

- Part sales

Our components are compatible with major truck and bus manufacturers, including DAF, Iveco, Man, Mercedes, Renault, Scania and Volvo, for chassis between 3.5T and 32T, as well as all tractor unit combinations.

Custom components, crafted with care

We listen carefully to your needs to provide a fully bespoke, end-to-end solution. We can oversee supply and fit or supply only, with the option of rapid response aftercare across the UK to keep you moving.

Whatever size your order, our trusted team will make your vision for your fleet a reality.